The only greywater system tested and certified by NSF to their 350 standard for commercial applications.

Aqualoop

Onsite Residential and Commercial Water Reuse Treatment

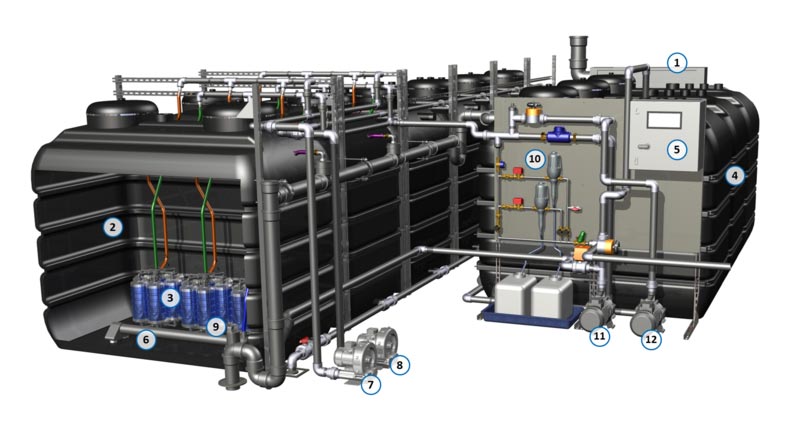

With our complete greywater systems, we offer a series of well thought-out, pre-assembled systems with internal tanks. The advantage of these package solutions is that all components are coordinated with each other. This leads to a fast project handling, little planning effort, easy installation and commissioning as well as safe operation of the system.

The only greywater system tested and certified by NSF to their 350 standard for commercial applications.

AQUALOOP pre-assembled, packaged systems minimize engineering, installation, commissioning, and start-up time for overall reduced installed cost. Each pre-assembled system is shipped shop-tested and ready for electrical and plumbing hook-up; with a complete drawing set, submittal package, and O&M manual.

- The only greywater system NSF 350 certified for commercial applications

- NSF350(C) assures low maintenance and high waterquality

- Greywater from showers, laundry, and bathroomsinks

- Commercial Scale Models from 160 to >12,000 GPD

- Patented Membrane Bioreactor Technology

Prefabricated greywater recycling systems

Functionality of AQUALOOP Greywater Systems

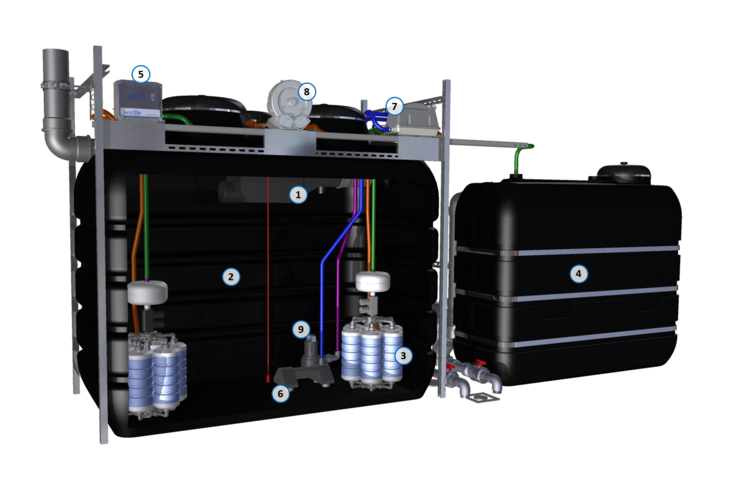

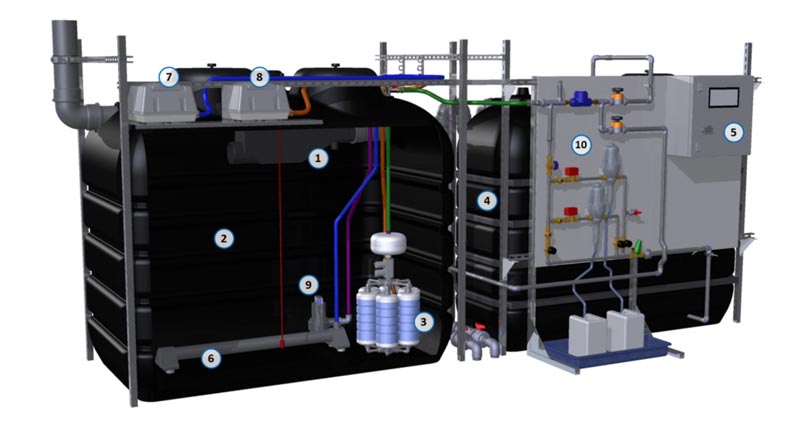

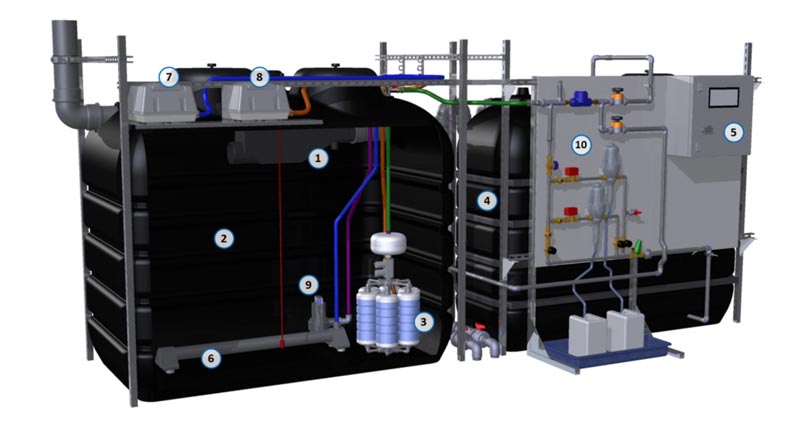

Prefiltration and bioreactor

In the AQUALOOP complete greywater systems, we use prefabricated, stable, opaque and reinforced internal tanks.

The greywater from showers, bathtubs and hand washbasins is pre-filtered through a highly efficient PURAIN filter before entering the bioreactor. The dirt collected in the PURAIN filter is regularly flushed back into the sewer using a backwash nozzle.

In the core of the plant, the bioreactor, continuous biodegradation takes place. This is achieved by means of a tubular diffuser located at the bottom of the plant and packing floating in the water. This fine-beaded diffuser, which is supplied with oxygen by a blower, creates an aerated fluidized bed, which is a prerequisite for the growth of bacteria within the greywater. Settlement occurs here on the many hundreds of AQUALOOP packed beds, which are special suspended bodies with a large surface area. A sludge pump, which is also located at the bottom, periodically removes any sediment that is formed.

Membrane station and control

The bioreactor also contains the AQUALOOP membrane stations, which filter the greywater into the clear water storage tank. For this purpose, all membrane stations with a treatment volume of 600 to 21,00 liters per day are equipped with a filtration and backwash pump. For plants with a treatment volume of 32,400 liters per day or more, one central filtration and backwash pump each is used. Due to the small membrane pore size of 0.02 µm, particles, bacteria and viruses are retained by ultrafiltration.

The membranes are periodically cleaned by backwashing and by coarse air bubbles. The three plants in the smallest category are controlled here with the aid of an AQUALOOP controller. Systems with a treatment volume of 5,400 l/day or more are equipped with the browser-capable I-CONNECT control system and the automatic chemical cleaning technology I-CON-ADS. This enables even more economical and low-maintenance operation, especially for the larger systems. Smaller systems, on the other hand, are equipped with the triple membrane surface to minimize the required maintenance intervals.

Further process

The clean service water is pumped to the consumers by our various pressure boosting systems, such as the RAINMASTER systems, depending on the calculated and required flow rate and pressure. The service water can be used for consumers such as toilets, washing machines or irrigation. In order to achieve the greatest possible safety, the already ultrafiltrated service water passes through a UV treatment as the last stage. The dimensioning of the UV disinfection system is done according to the dimensioning of the pressure boosting system.

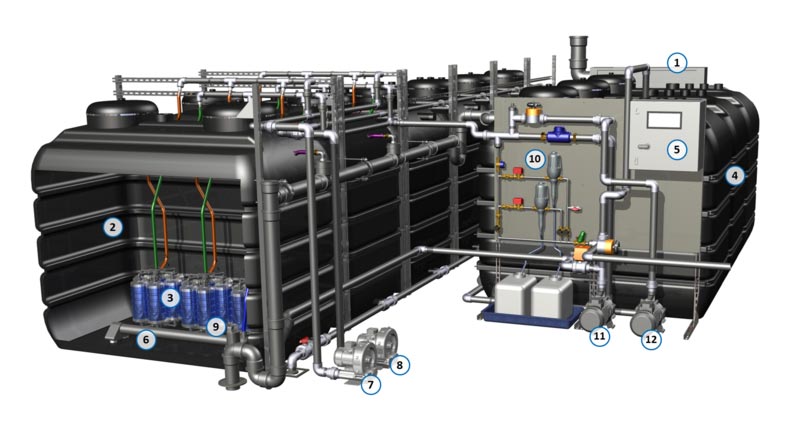

Aqualoop Packaged Models 1428-12,852 GPD

GW5400L – 1428 GPD

4XGW5400L – 5712 GPD

GW5400L – 1428 GPD

4XGW5400L – 5712 GPD

Overview of Pre-Assembled Complete Systems

| Greywater systems | Treatment [l/day] | AL control | I-CON-ADS | I-CONNECT | Centra filtration & backflush pump |

EU | US |

|---|---|---|---|---|---|---|---|

| AL-GW600 | 600 | ♦ | ♦ | ||||

| AL-GW1800 | 1,800 | ♦ | ♦ | ||||

| AL-GW3600 | 3,600 | ♦ | ♦ | ||||

| AL-GW5400 | 5,400 | ♦ | ♦ | ♦ | ♦ | ||

| AL-GW10800 | 10,800 | ♦ | ♦ | ♦ | ♦ | ||

| AL-GW16200 | 16,200 | ♦ | ♦ | ♦ | ♦ | ||

| AL-GW21600 | 21,600 | ♦ | ♦ | ♦ | ♦ | ||

| AL-GW32400 | 32,400 | ♦ | ♦ | ♦ | ♦ | ♦ | |

| AL-GW48600 | 48,600 | ♦ | ♦ | ♦ | ♦ | ♦ |